World Class Manufacturing Methodology as an Example of Problems Solution in Quality Management System

Por um escritor misterioso

Last updated 26 abril 2025

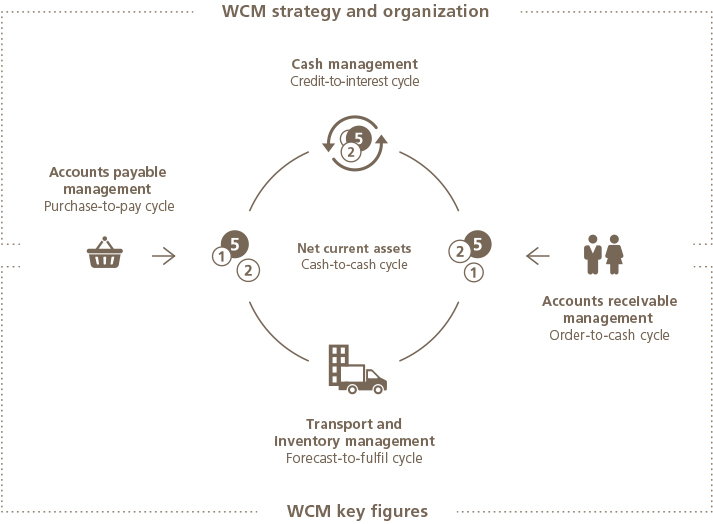

The article presents the methodology of World Class Manufacturing (WCM) used in one of the factory the mechanical engineering industry. The company has factories all over the world, while in Poland produces on average 800 ready-made machines by a year. The article presents the following pillars WCM: S (Safety) CD (Cost Deployment), Fl (Focused Improvement), AA (Autonomous Activity), PM (Professional Maintenance), QC (Quality Control), L & CS (Logistics & Customer Service), EEM (Early Equipment Management), EPM (Early Product Management), PD (People Development), E (Environment). Each pillar uses methods and tools. By using the methodology of WCM in the factory has reduced losses and improved the quality of the products.

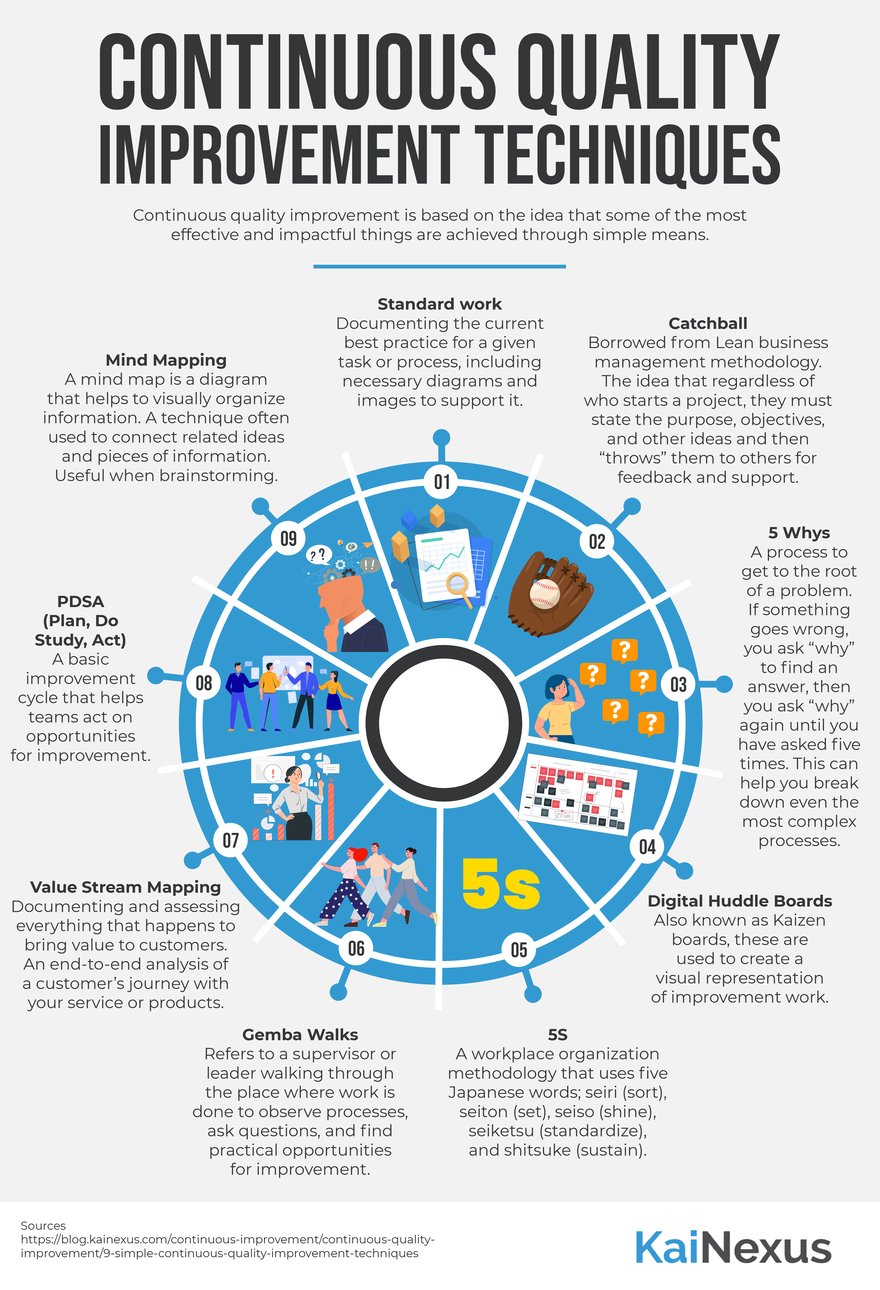

Elevate Excellence: Unveiling 9 Quality Improvement Techniques

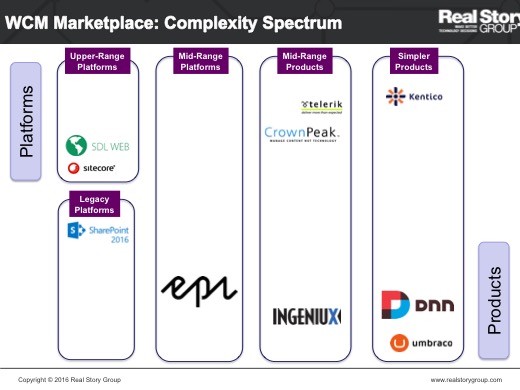

The World Class Manufacturing Framework [13]

PDF) A WORLD CLASS MANUFACTURING IMPLEMENTATION MODEL

7 Basic Tools of Quality for Process Improvement

Best Quality Management Systems (QMS) in 2023

:max_bytes(150000):strip_icc()/value-engineering.asp_Finish-8f3c9d6097f04c74ba49fce1603afdf5.png)

Value Engineering: Definition, Meaning, and How It Works

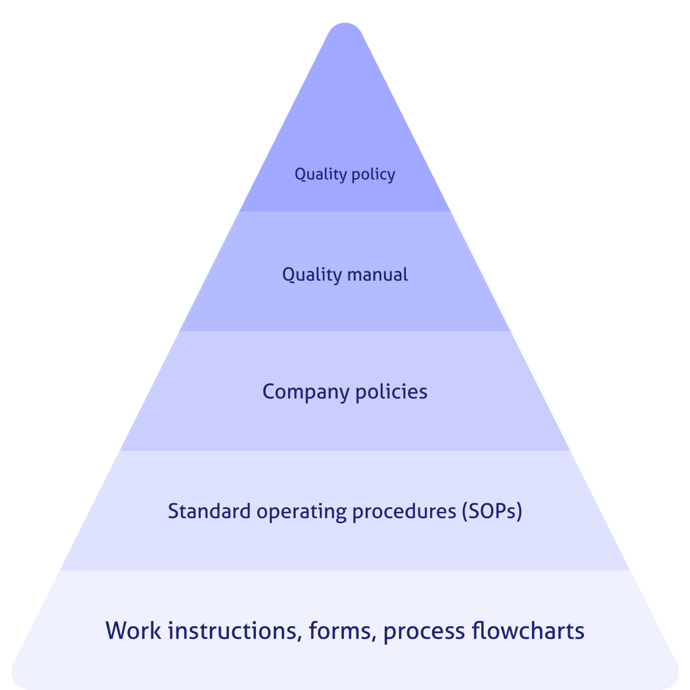

What are core elements of a quality management system (QMS

Problem-solving techniques for a high-performance team

PDF) QUALITY AND WORLD CLASS MANUFACTURING

10 Benefits of a Quality Management System for Life Sciences

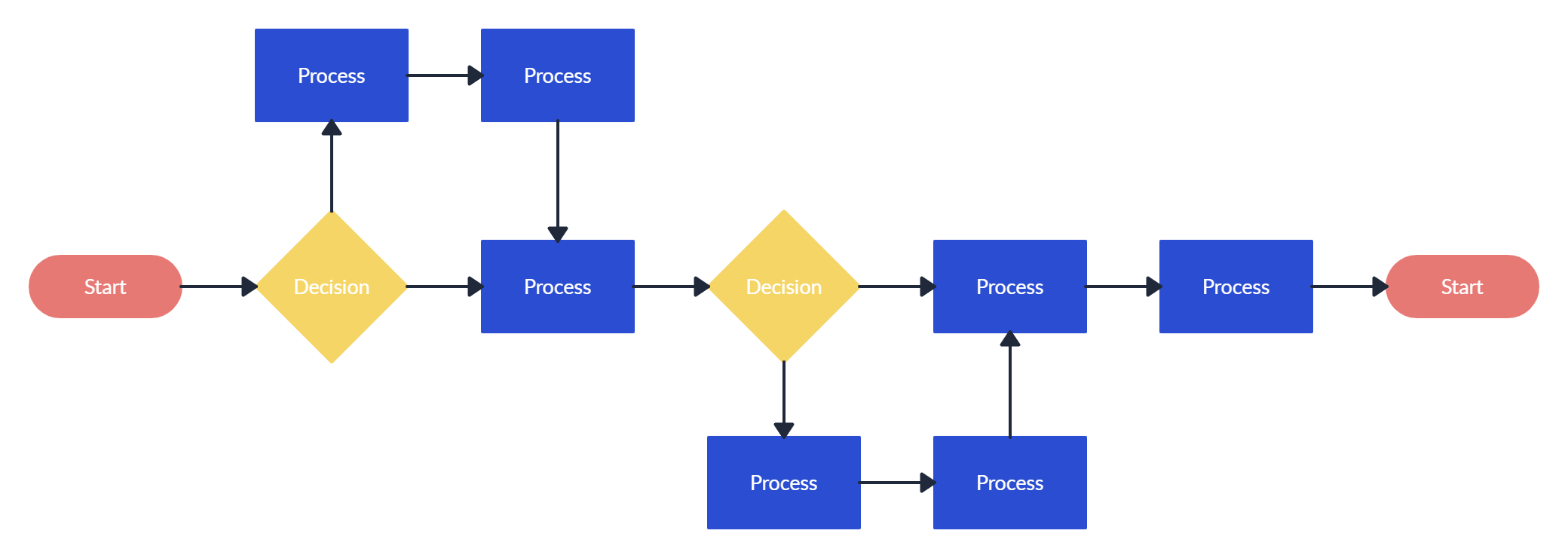

Sample Project Management Flow Chart (Free Tools Included)

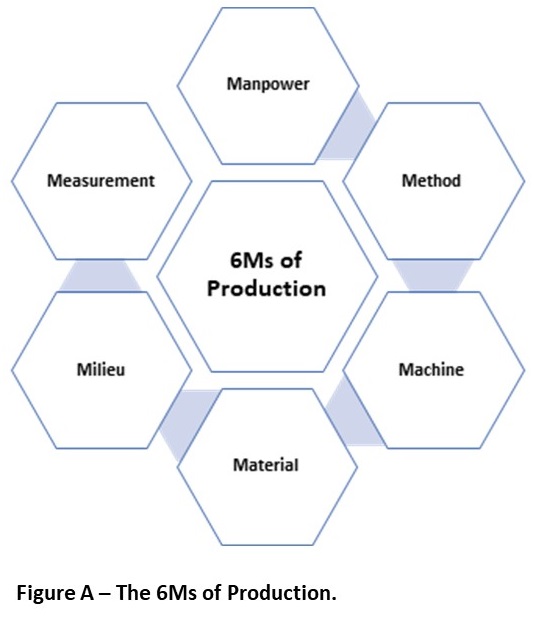

6Ms of Production (man, machine, material, method, mother nature

The Pareto Chart: How to Solve Problems & Make Informed Decisions

World Class Manufacturing Unit I II, PDF

World Class Manufacturing – Makigami Info